How it works

Technical Info

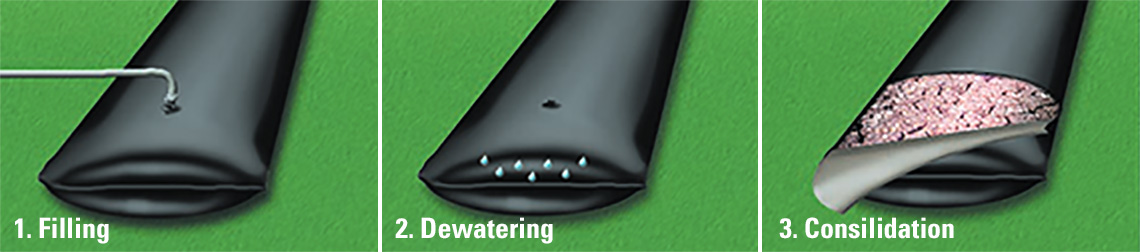

How TenCate Geotube® Dewatering Technology Works

Dewatering with TenCate Geotube® technology is a three-step process:

Step 1: Filling

Sludge (slurry material) is pumped into the TenCate Geotube® container. Environmentally-safe polymers are added to the sludge, which makes the solids bind together and water separate. The TenCate Geotube® container's unique fabric confines the fine grains of the material.

Step 2: Dewatering

Clear effluent water simply drains from the TenCate Geotube® container through the small pores in the specially engineered textile. This results in effective dewatering and efficient volume reduction of the contained materials. The volume reduction allows for repeated filling of the TenCate Geotube® container. Over 99% of solids are captured, and clear filtrate can be collected and recirculated through the system. The decanted water is often of a quality that can be reused/returned for processing or returned to native waterways without additional treatment.

Step 3: Consolidation

After the final cycle of filling and dewatering, the solids remain in the bag and continue to densify due to desiccation as residual water vapor escapes through the fabric. Volume reduction can be as high as 90 percent. When full, the TenCate Geotube® container and contents can be deposited at a landfill, remain on-site, or the solids can be removed and land-applied when appropriate.

How TenCate Geotube® Marine and Shoreline Technology Works

Geotube® Marine and Shoreline Technology is a permeable system fabricated from an engineered textile specifically designed for containment and shoreline erosion protection. The Geotube® system has unique designed strength, filtration, and retention characteristics to withhold sand or similar materials to act as a permanent or non-permanent containment structure:

Step 1: Filling

In the filling stage, the Geotube® container is filled with dredged sand or similar materials. The Geotube® containers are constructed of a unique fabric, specially engineered for a marine structure.

Step 2: Containment

In the containment stage, the durable and high retention fabric allows the dredged materials to fall out of suspension and form a dense monolithic structure.

Step 3: Structural

In the final stage, structural , the contained and densified material serves as a structural mass. When utilized with an accompanying Scour Apron, the Geotube® container may be utilized as a sand dune core or other shoreline re-nourishment or erosion prevention medium.